TMT bars

TMT (thermo-mechanical treatment) is a method of producing high-strength reinforcing steel bars. TMT bars are used for a variety of applications. TMT Bars are utilised in all types of construction because they offer the structure with maximum safety and durability. It’s utilised in civil building projects like roads, bridges, Power Plants, airports, Flyovers, and Dams. TMT steel bars should be corrosion resistant to protect your project’s safety and assist your structure in lasting longer.

The manufacturing process of TMT bars

There are five steps involved in making quality Thermo Mechanical Treatment bars.

Extraction of iron from its ore

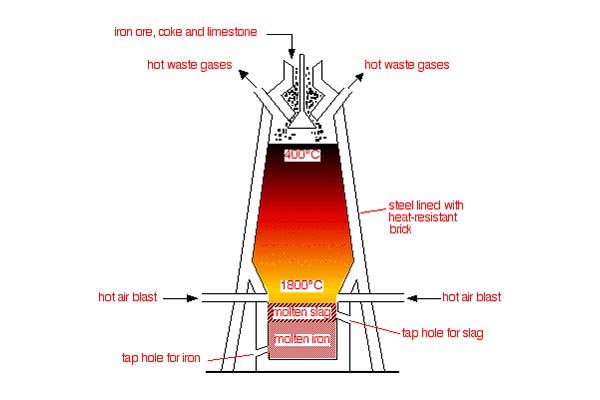

Iron ore is the primary starting point or raw material in steel production. Coal and dolomite are also used in the manufacturing process. According to TMT steel specifications, the iron ore is treated, mixed, and unmixed.

Raw materials such as iron ore, coke, or flukes extract iron kept molten. Following that, molten iron is pre-treated and transformed into steel in a converter before being heated in a spoon to refine the chemistry of the steel. The molten steel is then placed into a casting machine, producing billets with a 130 mm 2 or more surface area.

By the end of this step, the iron ore has been refined, the needed elements have been blended in the proper quantities, and all impurities have been collected separately as slag.

Conversion of iron to steel

An oxygen furnace is used to mix oxygen with carbon in the iron ore during this process. This pre-treatment removed the carbon dioxide in the mixture. After that, the under-process steel is sent through an EAF (Electric Arc Furnace) to refine its composition further.

In a steel factory, the critical casting stage for the form of TMT steel rods begins now. Molten steel is gradually moved from the EAF (Electric Arc Furnace) to the continuous casting process, where it is poured into water-cooled moulds. As the steel adopts the shape of TMT bars at this point, it solidifies.

Quenching

The hot rolled steel bars are placed into a water spray system known as the ‘Thermex System’ as soon as they exit the finished mill. The temperature of the outside layer of the steel bars is rapidly lowered during the process, causing it to harden while the inner core stays hot and flexible. The steel bars are ‘quenched’ throughout this process. The quenching process is used to fine-tune the hardness and ductility of steel bars to achieve the necessary qualities.

Self- tempering

After leaving the quenching box, a temperature gradient forms across the cross-section of the quenched bar. As a result, heat moves from the core to the outside surface at a greater temperature. This results in the correct tempering of the outer martensitic layer into Tempered Martensite and creating a Martensite-Banite intermediate ring. At this point, the core is still austenitic.

Atmospheric Cooling

Atmospheric Cooling is the fifth and last step in the TMT steel factory’s Thermo Mechanical Treatment of steel bars. After self-tempering, the nearly finished TMT steel bars are placed on a cooling bed set to ambient temperature. The austenitic core of the bars transforms into a ferrite-pearlite structure during air cooling.

As a result, TMT bars have the desired tensile strength and elongation required in construction.

Click here to purchase superior quality TMT Steel bar.