Different Types of TMT Steel Bars

TMT bars are commonly utilized in civil construction projects, including building beams, slabs, columns, and other structures. They must sustain all types of enormous loads as the core strength of every construction.

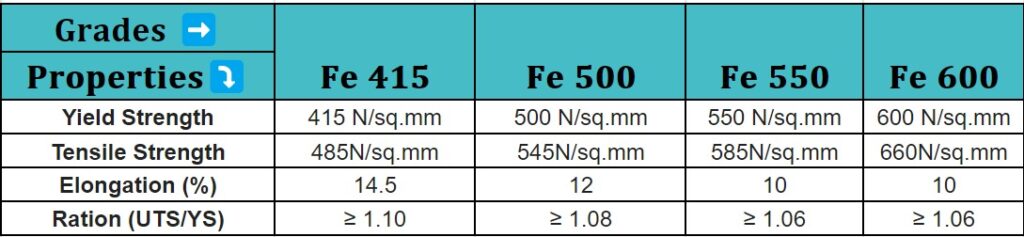

TMT bars are available in four categories in India they are Fe-415, Fe-500, Fe-550, and Fe-600. The numbers show the amount of force required to deform it, with the higher the grade, the stronger and superior the bar. The strength and stiffness of the materials are graded.

The Fe-415 grade is adequate for residences and residential buildings if Fe-600 bars are for hardcore industrial use. Fe-500 and Fe-550 grades are adaptable bars that can be utilised to build bridges and underground structures.

Now, let’s take a closer look at the various grades of these bars produced by TMT bar manufacturers in India.

Fe 415 grade TMT Steel Bar

Because of its cost-effectiveness and ductility, Fe 415 TMT bar is commonly employed in small-scale construction projects. It can easily be bent into the most complicated shapes, ideal for minor load buildings. These bars can be utilized in areas prone to earthquakes due to their uniform elongation property.

Fe-500 grade TMT Steel Bar

The Fe500 grade is recognised as a market standard in many construction projects.Fe500D and Fe 500S are popular variations of Fe500 that provide improved earthquake resilience and ductility.

Fe 500 TMT bars can be used in residential, commercial, and multi-story construction projects. They have higher tensile strength and ductility than Fe 415, specifically designed to provide stability and load resistance in high-rise constructions.

Fe 550 grade TMT Steel Bar

Fe 550 grade bars can be used in a variety of large-scale projects due to their increased tensile strength. These are utilised in developing industrial and large-format infrastructure projects, such as brides, industrial projects, and structures with excellent load-bearing capacity. These bars have a powerful impact on coastal, marine, and subsurface environments.

Fe 600 grade TMT Steel Bar

Fe 600 is one of the most long-lasting TMT grades used in heavy-duty infrastructure projects, including bridges and marine facilities. They provide higher tensile strength, lower overall consumption, and reduce steel congestion in the reinforcement. Expressways, metro Projects, factories, towers, commercial complexes, and industrial zones are built with Fe 600. They are frequently utilised in large-scale projects where significant load bearing, durability, and corrosion resistance are the characteristics of Fe 600.

Mechanical Properties of different types of grades of TMT Steel Bars

Yield Strength– Yield strength is a measurement of the most significant stress that a material can withstand without deforming plastically.

Tensile Strength – a maximum load that a material can support without fracture when being stretched, divided by the original cross-sectional area of the material.

Elongation – The percentage of the stretch from the steel’s initial length to the point of failure indicates how ductile it is.

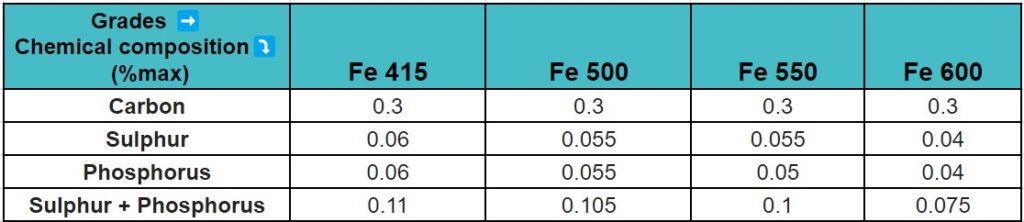

Chemical Compositions of TMT Steel Bars

The chemical compositions in TMT steel bars are maintained according to ISI (Indian Standards Institute) requirements. Carbon levels are kept well below the ISI standard, resulting in good ductility, high bendability, corrosion resistance and enhanced weldability.

Other undesirable impurities that reduce the overall lifetime of TMT bars, such as sulphur and phosphorus, are kept at far lower levels than ISI requirements.

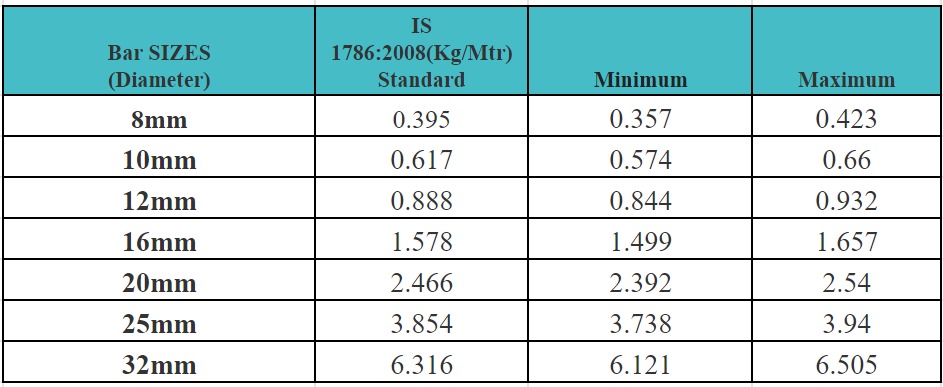

TMT steel bars are available in a variety of diameters that are 8mm, 10mm, 12mm, 16mm, 18mm, 20mm, 25mm, and 32mm, several well-known TMT manufacturers are now aiming to produce bigger diameters.

Here are the Specifications of various types of TMT Steel bars Sizes

As a result, picking the right TMT bar for your project is essential. Different projects may require other TMT bars depending on their size, strength, dimensions, and characteristics. As a result, you must first understand the requirements before selecting the right TMT bar.